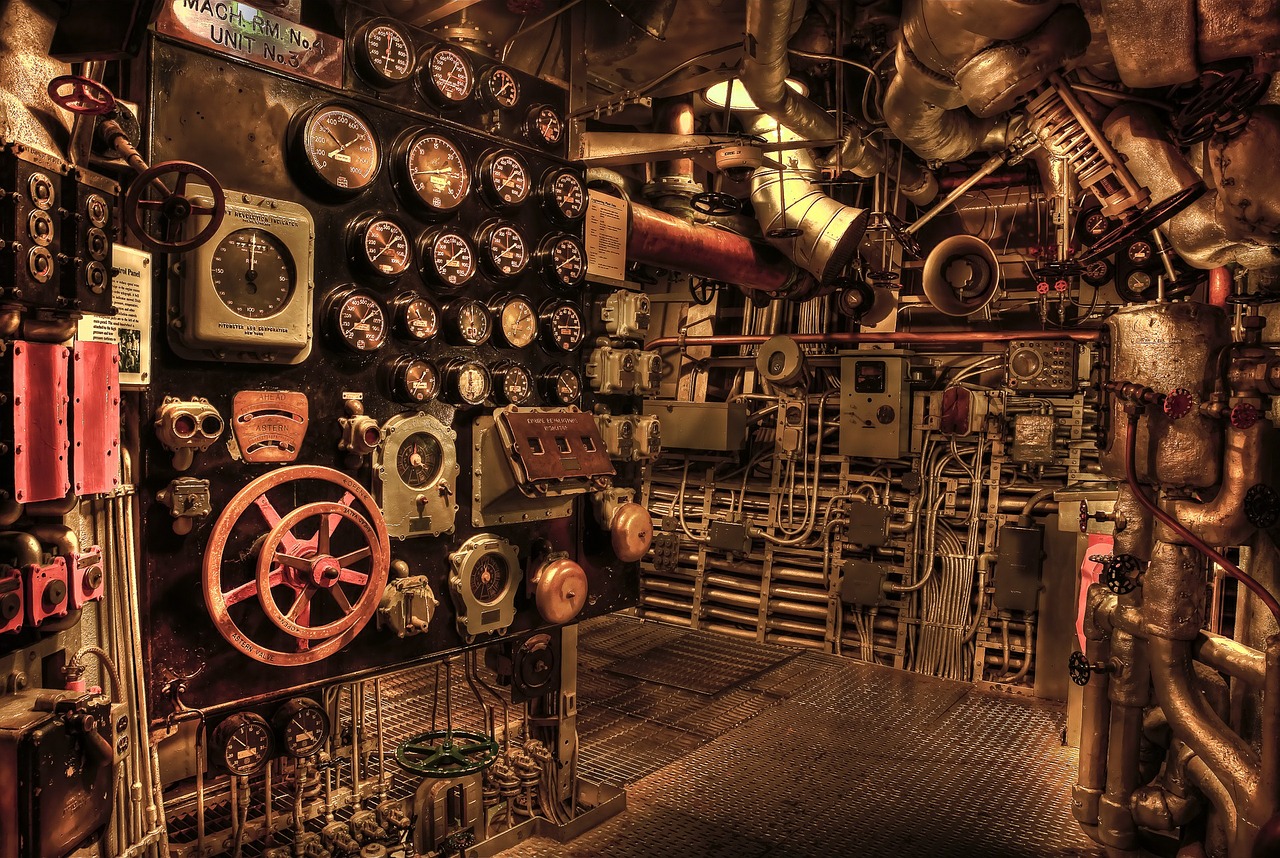

Uss Texas Engines - 1 of the 9 engine gauges and controls is visible in the engine room recently added to the Texas battleship tour after the overhaul.

2 of 9 The third deck, including the crew quarters, engine shop, radio room and engine room, is among the areas open to visitors following a two-year renovation project on the battleship La Porte.

Uss Texas Engines

4 of the 9 yellow boiler hanging platforms cover the walls of the battleship's third deck ammunition passage. Kirk Side / Staff Photographers Show more

Leaky Battleship Needs $35m In Repairs

5 / 9 The engine shop on deck three is among the parts of the battleship included in the tour.

7 of the 9 tours now have access to parts of the battleship that were closed during the renovation project. Kirk Sides / Staff Photographers Show more Show less

8 of the 9 sparse crew quarters were equipped with lockers, and a bunk can be seen on the third deck of the battleship Texas.

Until the recent completion of a two-year renovation project, visitors to the Texas Battleship were unable to enter La Porte's massive engine room and other key parts of the floating museum.

Battleship Texas Bb35 History 1919 To 1924

Now the work is complete, and the engine room, drying room, brig (compartment holding prisoners) and damage control locker are back on the road for passers-by on the only US Navy warship to have served in both world wars. .

"Now people can see the engines, and it's very interesting," said Stephanie Croat, assistant to the world's last dreadnought, launched in 1910. It still exists today.

"Not only are these huge, huge pieces of machinery, but they're actually the same type of engines that were used on the Titanic," he said.

He said it was important to get the necessary provisions for the ship to stay at anchor and stay at anchor. If fundraising efforts to save the ship fail and the warship is sunk, Crott said even repairs will be needed.

Where Is The Uss Texas Moving To?

He said many of the recent repairs to the interior structural parts of the ship were made with funds from the Texas Legislature. The ship is owned by the government.

"These repairs had to be done to move it at all," Crott said. “So if we could get her into dry dock, those structural issues would have to be addressed to stabilize her enough for that transition, and if we couldn't, she would have to. Loud enough to drive ships out of the channel."

Not all places closed to tours have been renovated. Some were located near repair sites, while others were used as temporary storage for equipment and other construction materials.

The first phase of the overhaul was carried out from 2014 to 2016 and focused on structural repairs under the engine. Recent work has included restoring the watertight integrity of some of the inner tanks. Both repairs cost $25 million each.

One Of The Triple Expansion Steam Engines Of Uss Vermont (bb 20) [2844 X 1873]

Designated a US National Historic Landmark, the ship participated in the Allied invasions of Normandy, Iwo Jima, Okinawa, and North Africa.

For years, the Battleship Texas Foundation has been trying to get funding to move the ship to a dry dock, which could cost $40 million or $50 million. Being in water causes the hull to rust and is constantly bent to eliminate leaks. The leaked water is pumped day and night. Engineers evaluating the ship say that without moving, the pumps and patches will not be enough against the salt water in the ship's channel.

"This ship is still sitting in the water and the hull is still rusting," Crott said. "We're hoping to get something out of the Legislature this session to put her in dry dock, but you never know what's going to happen. She's attached to her propeller and has no reduction gear.

The first motion drawings, dated September 29, 1910, were for a four-propeller turbine, the ARKANSAS design, producing 32,000 watt horsepower (about 4,000 piston engines at the time) at 330 rpm versus 125. In early December 1910, before the contract was signed, the USN changed the propulsion characteristics to piston engines. This difference was due to the fuel efficiency of the turbine at low speeds being much lower than that of the piston engine.

Battleship Texas Special Feature

The engines on the TEXAS and NEWYORK were the largest engines ever installed on a USN battleship. During sea trials off Rockland, Maine in October 1913, the ship's fastest recorded speed was 22.28 knots (25.25 mph) at 274psi steam pressure. During USN, 125 rpm, steam pressure 265psi, maximum speed was 21 knots in 1914 and 20.5 knots in 1945. (I'm surprised the 265psi steam pressure for NEW YORK is 280psi and max speed.)

By 1923, the Navy was again looking at installing turbines in TEXAS. Drawings have been made for placing the turbines in the boiler room and placing the boilers outside the turbines. In 1925-1927, when the ship underwent modernization, the engines were not changed.

Steam entered the engine at 265psi and passed through three piston cylinders of increasingly larger diameter (triple expansion); One 39 inch high pressure, 63 inch intermediate pressure and two 83 inch low pressure. (Some ocean liners had quadruple expansion engines). Steam pressure decreased as it passed through each cylinder, and the reduced energy was compensated by the increased surface area of the piston for the steam to expand. When both low-pressure pistons were filled with steam, the volume of steam consumed was 10.6 times greater than the original volume entering the high-pressure cylinder.

Engines were single-stroke (double-acting): Unlike a four-stroke car engine or two-stroke motorcycle, BB35 engines were single-stroke. Each up and down movement of the pistons was a power stroke as steam entered the top and bottom of the pistons. During the power stroke, the steam on the opposite side of the cylinder was exhausted to the next cylinder (or condenser in the case of a low-pressure cylinder). 48 inches is the length of the engine stroke.

Battleship Texas Bb35 Steering Engine Room

When the steam exited the low-pressure cylinders, the pressure was below atmospheric and had to be pumped into a condenser on board each engine. Cold brine was circulated through the condenser to convert the hot steam to fresh water, which was then pumped into the fresh water supply tanks to be used by the steam boilers to make steam that returned to the engine.

Steam Cutoff: All steam is cut off to keep the engine running. To cool the engine evenly, the engine rotates mechanically with gears to prevent warping. The crank has a gear with large brass teeth. The worm gear engages with brass teeth and connects the worm gear shaft to the 15 hp motor through a series of reduction gears. According to the BB35 drawing, one rotation of the crank takes about 7.5 minutes.

COLD ENGINE STARTING: According to a 1941 US Navy document for large steam recirculation operation, a TEXAS engine takes 1.5 to 2 hours to be ready to run on a cold start.

Fuel efficiency: Piston engines were more fuel efficient at lower speeds than most turbines. A US Navy fuel consumption chart in July 1935 shows that the US battleship had 6 gallons of fuel oil at 15 gallons at 6 knots, while the Texas had 6 gallons of fuel at 15 gallons. (The other 4 turbine ships and New York used less fuel than Texas). The TEXAS engines used more fuel than the New York at all speeds, and the difference increased as speed increased. The TEXAS engines were 10 knots more fuel efficient than the OKLAHOMA.

Living Our Dream: Mobile, Al Part I: Uss Alabama

Beds - Beds are made of cast steel, each in three sections, bolted together and supported on Kelson plates. Main bearings, columns, etc. appropriate seats and faces are also provided.

Main Bearings - The main bearings consist of a low brass cast steel cap each coated with white metal and turned for cooling water circulation.

Frame - Engine frames consist of ordinary naval forged steel bars attached to bedplates and cylinders and fitted with suitable diagonal, cross and longitudinal braces.

Cylinders - Cylinders and valve cases are cast iron with running liners mounted in cast iron close enough to operate properly. All cylinders, except the high pressure one, are steam coated around and on both sides of the working liner.

Oc]the Steam Steering Engine In The Back Of The Starboard Engine Room On The Battleship Texas[3024 X 4032]

Pistons - All pistons are conical design, cast iron for high pressure cylinders and steel for the rest. High pressure followers cast iron and those

Uss texas dry berth, uss texas battleship, uss missouri engines, uss texas model, uss texas, uss iowa engines, uss texas 1892, uss texas ship, uss texas museum, uss texas bb 35, uss texas battleship model, uss texas model kit

0 Comments